The Society of Mingu of Japan is different from the many other engineering societies involved in developing advanced drones and robotics. Still, they emphasize the transmission of traditional techniques through records. The Mingu has evolved as an extension of the human hands, and their forms and functions have attracted researchers in this field.

Focusing on the shape of Mingu, we can see that they are composed of organic curves and curved surfaces that are not found in modern industrial designers’ products these days. The shape can respond to the force of a human. An example of the mechanical rationality is the relationship between a center of gravity and a support position. Suppose the center of gravity and the support position held by a human hand is the same. In that case, the whole tool can be easily pulled up. If the center of gravity and the support position are far from each other, it is possible to generate force using the principle of leverage.

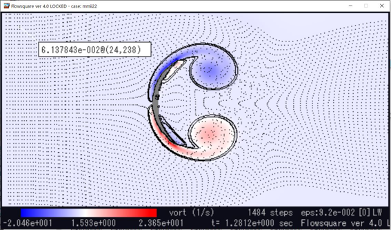

In our lab, we focus on the delicate balance of forces hidden in the structure of Mingu. For example, farming tools called Mi, which have been manufactured since ancient times to separate hulls and dust during grain threshing, are known as "winnowing" tools. The "Kizumi-no-Fuji-Mi", which is designated as a national intangible cultural asset by the city of Sosa City in Chiba Prefecture, is made of wisteria's thin bark and split bamboo strips and is characterized by its lightness and elasticity.

A computational fluid dynamics (CFD) simulation of the shape of the Mi shows that its basic form is the natural bending of the elastic material. This basic shape can generate a downward flow of air by a massive vortex. In other words, the combination of material and form of the Mi is supposed to make it possible to blow away rice husks efficiently when the Mi is swung down. The existence of structural rationality in the shape of these folk tools shows that the combination of materials and form has the best structure as a tool.

For example, the wood's stiffness differs depending on the fibers' direction, and masterful artisans of Mingu have taken advantage of such an anisotropic property of the wood to create tools for agricultural work. Since lightweight and rigid features are also required for drones, we can utilize the outputs from Mingu research to determine drones' materials. Moreover, if we can look at the evolutionary process of birds and tools at the same level and apply it to drone development, we may be able to reveal the optimal structure necessary for the general function of flight.

Reference

- [1] M. Kubo, Y. Kitamura, and T. Tauchi: An Attempt of Structural Mechanics Consideration for the Form of Mingu - On the Mechanical Rationality of Mingu Form (Mechanics), in Japanese, Mingu Kenkyu, No. 153, The Society of Mingu of Japan, 2016, in Japanese(久保光徳, 北村有希子, 田内隆利:民具の形に対する構造力学的考察の試み ―民具形態の力学的合理性(力学性)について―, 『民具研究』153号, 日本民具学会, 2016.04).

Profile

Mitsunori Kubo

Graduated from the Department of Aeronautics and Astronautics, Graduate School of Engineering, University of Tokyo in 1989, and received PhD. After working as a research assistant at the Faculty of Engineering, Chiba University, current position since 2009. He specializes in modeling mechanics, structural dynamics, and vibration engineering and investigates the dynamics of shapes created by human hands.